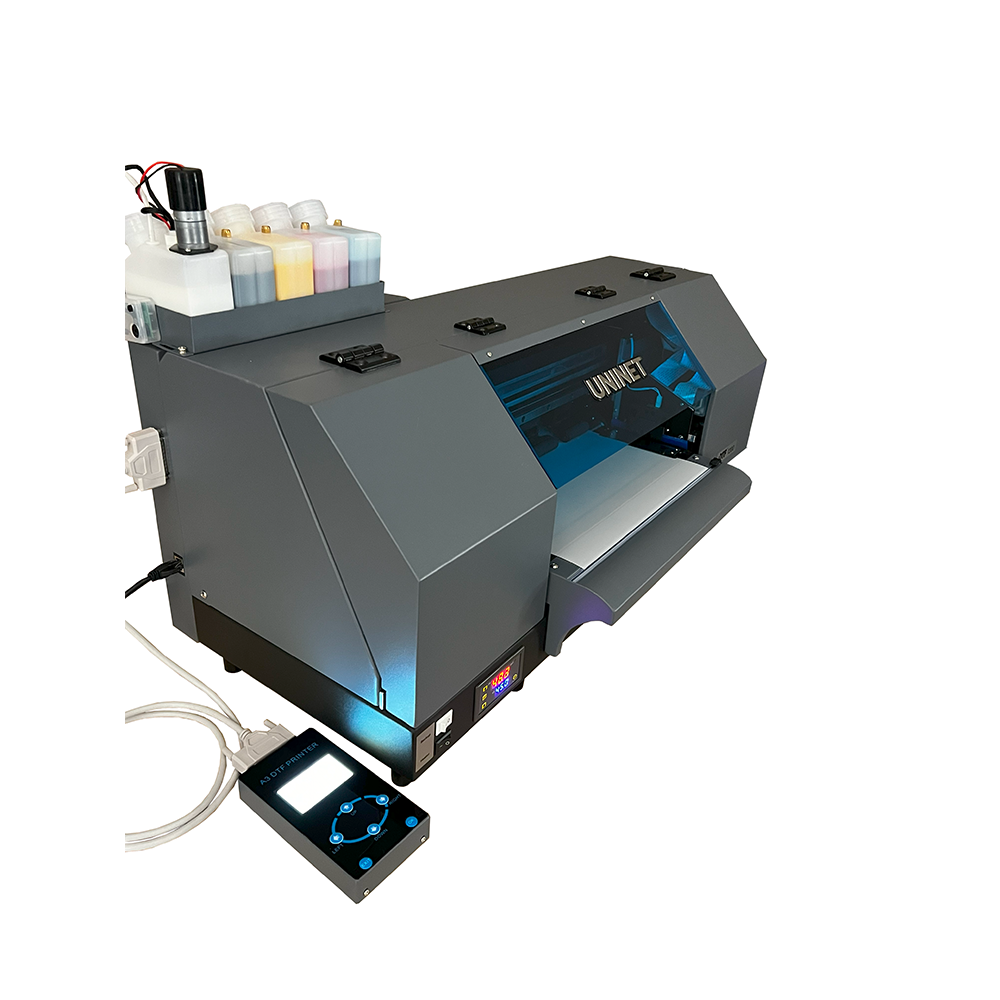

Uninet DTF 1200 13" Dual Head Direct to Film Printer

Talk to our team of experts to get 1-on-1 personalized information and have your questions answered in real time!

($200 value)

. Added to cart automatically; remove to opt out. Enjoy lifetime setup, troubleshooting, and expert help—free!

Terms apply

($200 value)

. Added to cart automatically; remove to opt out. Enjoy lifetime setup, troubleshooting, and expert help—free!

Terms apply

Why Choose HeatPressNation?

With over 15 years of experience, HeatPressNation has established itself as the trusted industry leader in heat transfer solutions, earning the confidence of thousands of satisfied customers.

Thank you for your submission!

We will get back to you soon.

Bring your designs to life with the UNINET® DTF™ 1200 — the industry's fastest 13” wide DTF printer. Its dual printhead system delivers stunning, full-color transfers with unmatched speed, precision, and efficiency, making it the perfect solution for short-run, high-impact custom apparel production.

From Desktop to Designer Quality.

Introducing the UNINET® DTF™ 1200 — a compact, ink-based direct-to-film digital transfer printing system with a roll feeder, capable of printing up to A3+ (13-inch wide). Designed for short-run, on-demand production, it delivers exceptional, full-color print transfers for the custom apparel decorating market. Apply your creations to light or dark garments with ease and confidence — because with the DTF™ 1200, your designs deserve the runway treatment.

Small Frame. Big Performance.

Don’t let its desktop footprint fool you — this is a powerhouse. The DTF 1200’s 13-inch print width, dual printhead system, and production speed of up to 45 sq ft/hr give you professional results in a size that fits your workspace. Perfectly configured for manual or automatic powder application, it creates weedless, stretchable, durable, vibrant transfer prints in a single pass — whether your design is bold and intricate or soft and subtle.

Your Fast Track to Fashion Statements.

Think of it as your personal print studio — right on your desktop. Create custom apparel, accessories, sportswear, home décor, and more using fabrics like cotton, polyester, spandex, vinyl, nylon, leather, canvas, linen, and even chemical fiber blends. Your fashionable designs will emerge brilliantly colored, soft to the touch, and made to last — giving your customers (or yourself) pieces that feel as good as they look.

Expand Your Potential.

Want a complete, automated workflow? Pair the DTF™ 1200 Transfer Printer with the UNINET® DTF™ 14 Automated Powder Application & Curing Machine (sold separately) to handle powder application, curing, and drying automatically. This upgrade transforms your printer into one of the most cost-effective, fully integrated DTF solutions available.

Precision. Power. Perfection.

The DTF™ 1200 Transfer Printer features dual high-definition professional inkjet printheads for fast, accurate, high-quality printing. Its wide color gamut ensures crisp, stunning images, while White Overprint®® technology lays down CMYK + white ink in perfect alignment — giving you sharp, vibrant, professional-grade results every time.

The UNINET® Seal of Quality.

Every UNINET product carries the trusted UNINET seal of quality — a standard earned over years as one of the world’s most respected printing solution providers. The UNINET® DTF™ 1200 is no exception. With premium consumables, transfer films, and cleaning solutions, UNINET delivers a complete, streamlined system that helps printing professionals turn ideas into vibrant creations — faster and easier than ever.

Other Key Performance & Reliability Features:

- Printer Roll Feeder with auto-feeding capabilities

- Ink Tanks with Continuous Feed System

- Integrated WICS, White Ink Management System (prevents white ink particles from settling and reduces printhead clog).

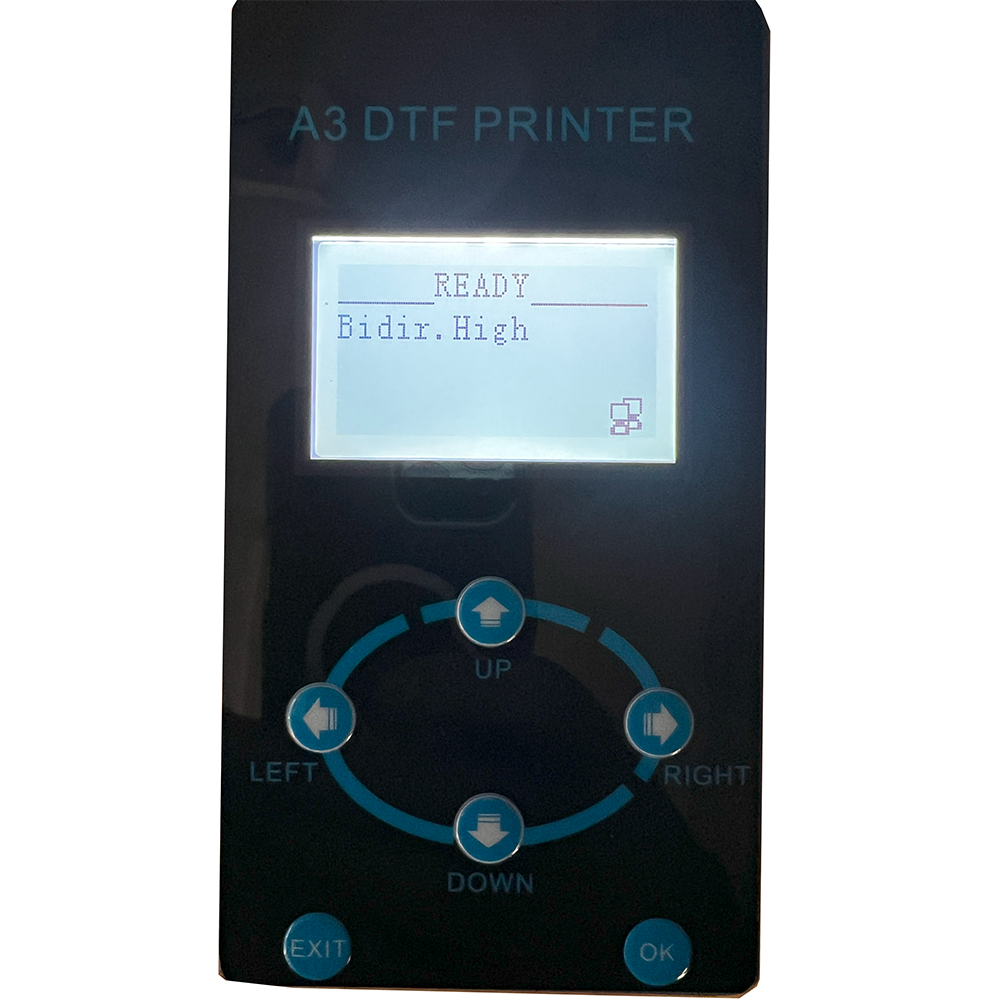

- Control Panel attached (makes controlling the printer easier).

- Built-in Film Cutter (slices the transfer away instead of using a pair of scissors).

- Built-in Auto Printhead Clean Technology (allows the user to set desired time sequences).

- Humidity and Temperature Sensor

- Internal Controllable Vacuum Suction Platform (prevents film buckling).

- Integrated Strike Sensors (protect the printheads and avoid damage).

- Three-Part Top Cover (for simplified maintenance).

- Reflective Plate (easier printhead maintenance).

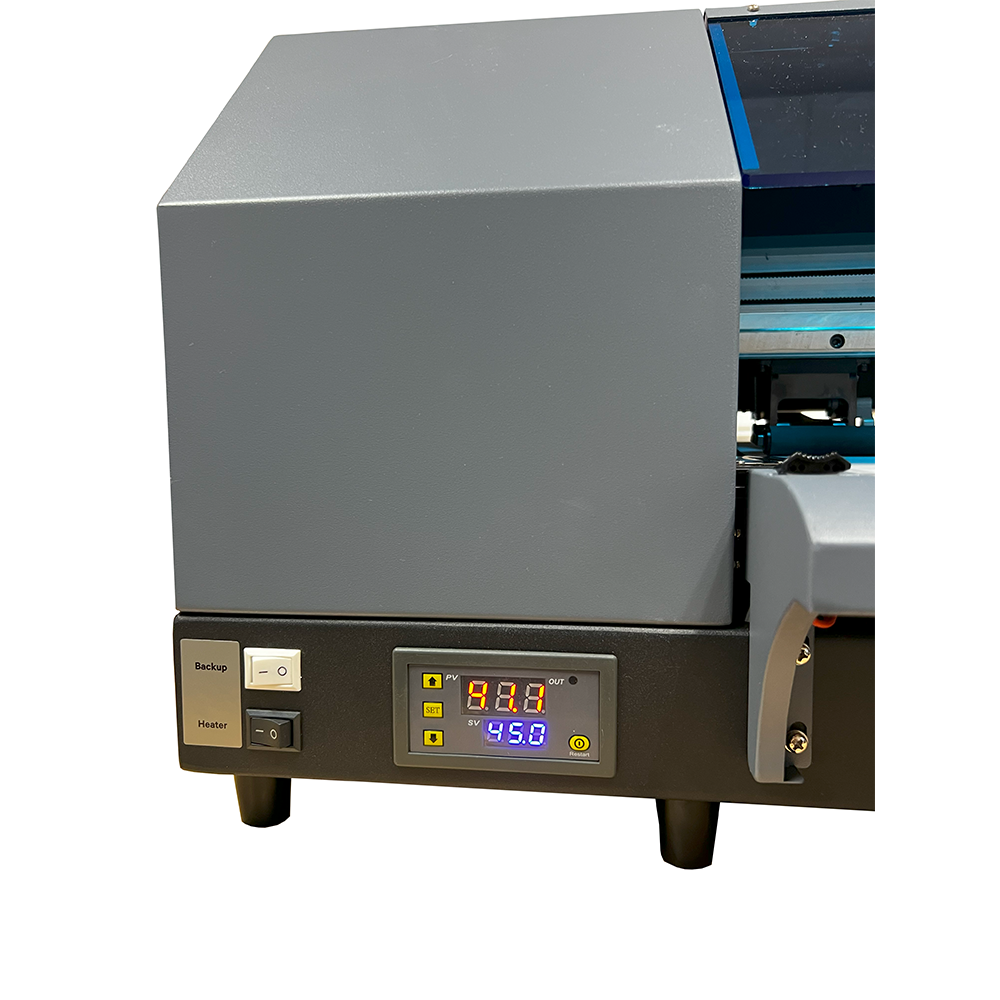

- Platen Heating System (for efficient and consistent job printing).

- Printhead Carriage rides on a high quality rail and slider (ensures smooth running operation and high-quality prints).

- Unparalleled Capping Station technology (protects printheads from drying out).

- Convenient Pause Button (pauses printing).

- Motherboard and control boards installed at the back of the printer (allows easier maintenance and prevents printer damage from accidental ink spills).

- UNINET® DTF™ 14 Auto Powder Unit, as an optional upgrade, can be paired to the DTF™ 1200 transfer printer to enable fully automated powder application, curing, and drying for a comprehensive printing solution. (Optional upgrade, sold separately).

Benefits of Direct to Film Transfers:

|

Any Color, Any Material: DTF transfers seamlessly adhere to multiple fabric types, regardless of color. Decorate cotton, nylon, polyester, leather, denim, and more. Unlock a world of vibrant possibilities for your designs! |

|

Easy to Use: Heat and pressure are all you need to transfer your designs. No need for pretreatment spray or tricky adhesive sheets. The transfer process is so simple that you can even sell your transfers for customers to apply themselves. |

|

Durable: Engineered to withstand the test of time, DTF transfers boast unparalleled durability, ensuring that your designs remain vibrant and intact through countless washes and wears. |

|

Soft and Stretchable: DTF transfers offer a silky-smooth touch and unparalleled stretchability, ensuring maximum comfort and freedom of movement with every wear. |

|

Long Shelf Life: With proper storage, DTF transfers can last for 1 year or longer. Print your more popular designs ahead of time, and press them on your schedule. |

What's Included:

- Dual Head High-Definition, Professional Inkjet Printhead System

- UNINET® DTF™ ProRIP™ Advanced RIP Software features exceptional file preparation, white and color management, production automation functionality, and more.

- UNINET® DTF™ Training and Onboarding: Discover everything there is to know about DTF™ printing, maximize the value of your equipment, and be inspired to expand your business even further.

- UNINET® DTF™ Five-color inks (CMYK + White), 1 liter bottles

- UNINET® DTF™ Transfer Powder, 1.75lb bag

- UNINET® DTF™ 13" Film Roll – 100 meters/328 ft

- UNINET® DTF Starter Bundle (Hygrometer, Maintenance Solutions & Accessories)

Not Included, but Also Needed:

- Powder Curing Heat Station (cures adhesive pretreat powder that is applied to printed film)

- Fume Extractor for Heat Station (some heat station models feature built-in fume extractor)

-

Heat Press (used to press final print to garment - 16" x 20" recommended)

- Humidifier (to keep the humidity above 50% in the print room)

- Computer with Windows 10 or higher and an available USB port

Specifications:

- PRINT SPEED: Up to 45 square ft / hr

- RESOLUTION: 1440 dpi

- PRINTHEAD: high definition, professional dual Printhead inkjet system

- OPERATING SYSTEM SUPPORTED: Windows® 10 and above

- INTERFACES: Network Line, RJ-45

- PAPER CAPACITY: Transfer film roll Up to 13 in / 330 mm wide X 328 ft / 100m long

- DOCUMENT FORMAT: PDF, JPG, EPS, TIFF, BMP

- INK: Water-based DTF ink; CMYK + White

- COLOR MANAGEMENT: ICC, RIP Software

- POWER: 60 HZ, 120V-4A

- WEIGHT: 66 lbs

- SIZE: 32 in x 14 in x 14 in

*This product is FINAL SALE*

WARNING: Work in a WELL VENTILATED AREA and use protective equipment when working with DTF products and processes. It is highly recommended the use of a Fume Extractor to handle the fumes caused by TPU adhesive powder curing. Bodily protection, including the use of PPE equipment such as a full body covering, a respirator / N95 mask, goggles and gloves are recommended to protect against TPU adhesive powder (prior to curing) that may become airborne due to handling. Inhalation of TPU adhesive powder or fumes may be hazardous to your health. The use of DTF equipment, chemicals, powders, inks and all accessories are at the sole risk of the user. DTF equipment is intended for use in a commercial environment. It is not recommended to use DTF equipment in a residential, or in-home setting. DTF inks and film require a good humidity environment - over 50% humidity is highly recommended to minimize the risk of ink clogs and film buckling. Add a Fume Extractor to this package for sufficient fume extraction.

DTF printers require daily use/maintenance! You must perform a head cleaning, nozzle check and a test print every day to ensure the printer is running smoothly and to prevent printhead and capping station clogs. Printheads and capping stations are considered consumables and are not covered under warranty if they clog. Clogs can occur even after one print, so maintenance must start the moment you install ink.

Explanation of Uninet Maintenence Solutions

The HPN MyExpert Support guarantee is our commitment to Lifetime Technical Support. No matter where you are in your product's life cycle, we will be here to provide support to your product and make sure you are fully covered.

Our MyExpert Support will always be there for you so you can purchase with confidence!

In addition, Uninet, the manufacturer, offers a 1-Year (parts and labor) warranty on this product. For warranty claims, we may need to involve the official Uninet team depending on the reported issue.

The HPN MyExpert Support guarantee is our commitment to Lifetime Technical Support (A $200 Value included with your purchase). No matter where you are in your product's life cycle, we will be here to provide support to your product and make sure you are fully covered.

Often imitated, never duplicated; our dedicated team of technicians are capable of providing support to your product at any point of its life. Whether it be during the setup process or even years down the line where troubleshooting may be required, they'll have your back and provide a solution.

Our MyExpert Support will always be there for you so you can purchase with confidence!

We're here to help you with:

- Technical Support

- Equipment Consultations

- Troubleshooting

- Business Tips

- & More!